SafeTrack

SafeTrack-1 Insulated Conductors

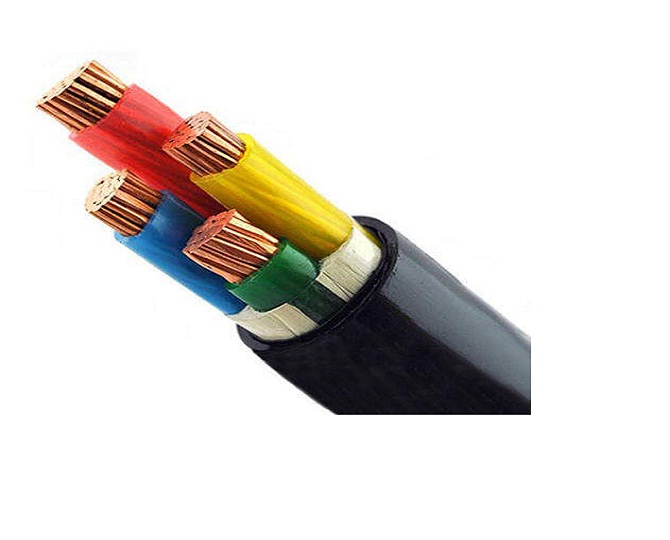

Safetrack-1 insulated conductors are designed in accordance with international regulations for a multitude of power supply applications. These conductors are compact, insulated, easy to install, in a horizontal or vertical configuration. They require much less space compared to conventional bare conductor systems.